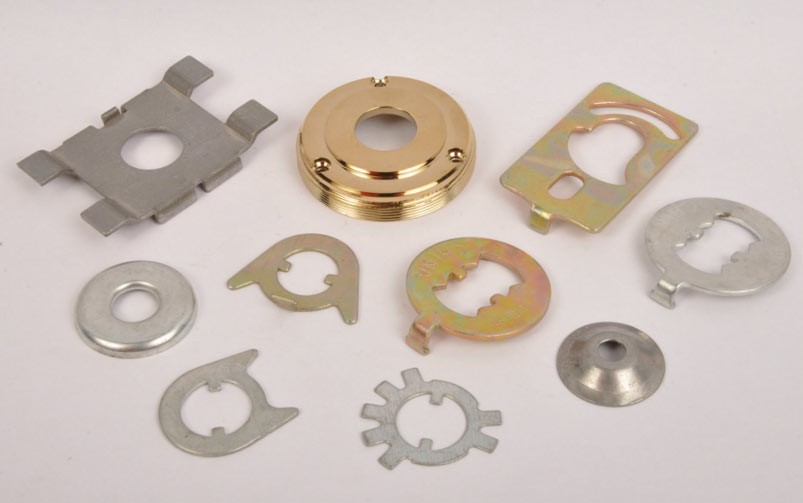

Stamping products

Stamping is an efficient production method. Using compound dies, especially multi-station progressive dies, multiple stamping processes can be completed on one press (single-station or multi-station) to realize strip uncoiling and straightening. Fully automatic production from flattening, blanking to forming and finishing. High production efficiency, good working conditions, low production cost, generally hundreds of pieces per minute can be produced. Compared with other methods of mechanical processing and plastic processing, stamping processing has many unique advantages in both technical and economic aspects.

(1) The production efficiency of stamping processing is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because stamping relies on punching dies and stamping equipment to complete the processing. The number of strokes of an ordinary press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even more than a thousand times per minute. May get a stamped part.

(2) When stamping, because the mold guarantees the size and shape accuracy of the stamping parts, and generally does not damage the surface quality of the stamping parts, and the life of the mold is generally longer, the quality of the stamping is stable, the interchangeability is good, and it is "identical." Characteristics.

(3) Stamping can process parts with a large size range and more complex shapes, such as stopwatches as small as clocks and clocks, as large as automobile longitudinal beams, covering parts, etc., plus the cold deformation and hardening effect of the material during the stamping, and the strength and strength of the stamping The stiffness is relatively high.

(4) Stamping generally does not generate chips and scraps, consumes less materials, and does not require other heating equipment, so it is a material-saving and energy-saving processing method, and the cost of stamping parts is lower.

簡體中文

簡體中文