Laser cutting technology is widely used in the processing of metal and non-metal materials, which can greatly reduce processing time, reduce processing costs, and improve workpiece quality. Modern lasers have become the "sword" of "cutting iron like mud" that people dream of. Take Jinyun Laser CO2 laser cutting machine as an example. The whole system is composed of control system, motion system, optical system, water cooling system, smoke exhaust and air blowing protection system, etc. It adopts the most advanced numerical control mode to realize multi-axis linkage and laser control. Speed-affected equal energy cutting, while supporting DXP, PLT, CNC and other graphic formats and strengthening the interface graphics drawing processing capabilities; using superior performance imported servo motor and transmission guide structure to achieve good motion accuracy at high speed.

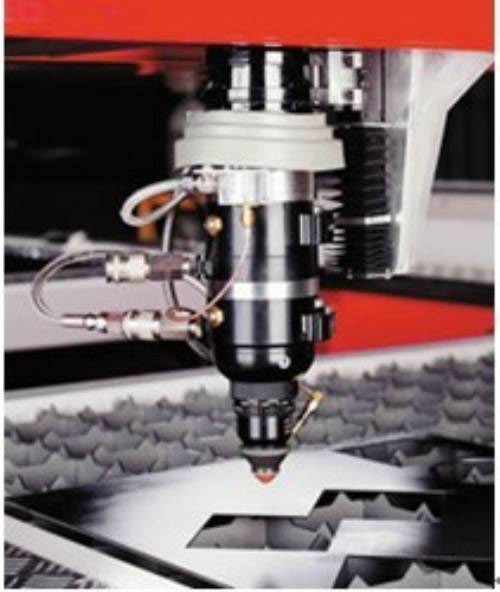

Laser cutting is achieved by applying high power density energy generated after laser focusing. Under the control of the computer, the laser is discharged through pulses, thereby outputting a controlled repetitive high-frequency pulsed laser to form a beam with a certain frequency and a certain pulse width. The pulsed laser beam is guided and reflected by the optical path and focused by the focusing lens group. On the surface of the processed object, a small, high-energy-density light spot is formed. The focal spot is located near the surface to be processed, and the processed material is melted or vaporized at an instant high temperature. Each high-energy laser pulse instantly sputters a small hole on the surface of the object. Under computer control, the laser processing head and the processed material perform continuous relative movement according to the pre-drawn pattern, so that the object will be processed into The shape you want.When cutting, an air stream coaxial with the beam is ejected from the cutting head to blow the melted or vaporized material from the bottom of the incision. The additional energy required; the airflow also cools the cut surface, reduces the heat-affected zone and ensures that the focusing lens is not polluted). Compared with traditional plate processing methods, laser cutting has high cutting quality (narrow cut width, small heat-affected zone, smooth cut), high cutting speed, high flexibility (can cut any shape at will), and a wide range of materials Adaptability and other advantages.

簡體中文

簡體中文